Around the end of 2012 I had become extremely frustrated with my Compak K10. Its mess, its noise, its size, having to sweep out the chute after each shot, trying to keep the doser clean, the stalling (finally fixed after almost a year of messing with it) -- all these things were adding up to one dissatisfied home barista. After looking at the options, I resigned myself to designing my own grinder. Not an easy task for someone with a small lathe and basically no other metalworking tools, but something had to change. Then, the HG one fell out of the sky. Sure, it didn't have a motor, but everything else was there -- a big conical burr set, direct grind path, precise machining, small size, good looks.

I actually used the HG one without a motor for about 6 months. It's really not a bad experience -- definitely better than a K10 or similar pro grinder. But hand grinding eventually got old, and I began searching for a way to motorize it. The solution was guided by two things: I wanted a 100% reversible modification, and I wanted to used the motor I already had in my parts bin.

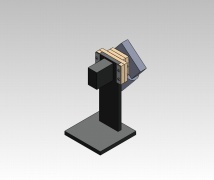

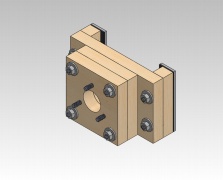

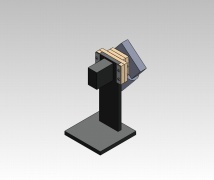

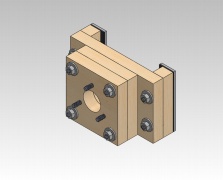

Below is a rendering of the motorized HG one (simplified) and the motor mount.

I turned the shaft adapter on my lathe, but the rest of the motor mount can be built with simple hand tools. The pictures below show the HG one in various states of evolution. For a while I used the 3D-printed portafilter holder, but now I use a catch-can that sticks to the magnets on the bottom of the burr assembly. The extra large dosing funnel was purchased from a Home-Barista.com member, and it really helps keep beans from jumping out the top of the grinder. 24V power for the motor is provided by a Mean Well SE-600-27.